Introduction to Through Hole PCB Assembly

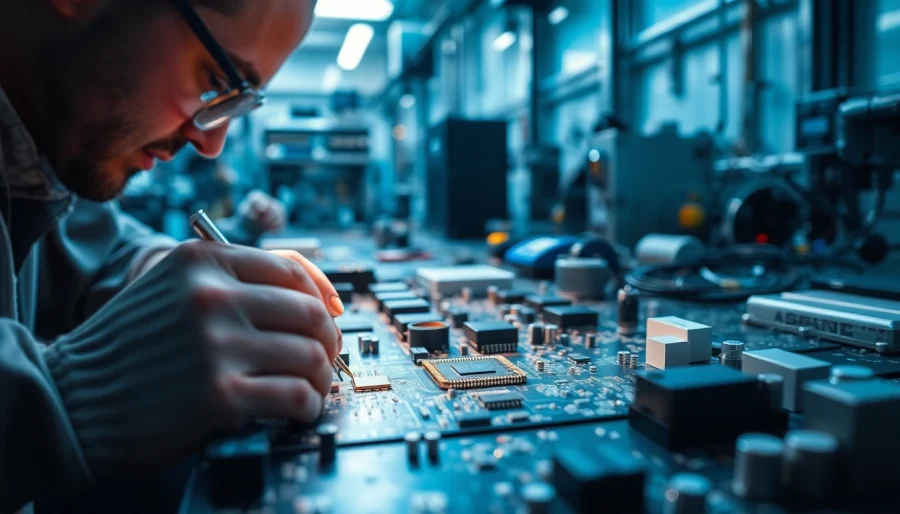

Definition and Overview of Through Hole PCB Assembly

Through Hole PCB Assembly is a well-structured method for attaching electronic components to a printed circuit board (PCB) through the use of pre-drilled holes. This technique is essential for ensuring that the leads of components are securely inserted through the PCB, establishing a connection on the reverse side. The process involves inserting components into the holes and soldering them in place, making it vital for high-reliability applications. This method stands apart from surface mount technology (SMT), which involves mounting components directly onto the surface of the PCB. The choice between these two methods often hinges on the specific requirements of the design and intended application.

Importance of Through Hole PCB Assembly in Electronics

Through Hole PCB Assembly plays a crucial role in the electronics industry due to its reliability and versatility. The mechanical stability provided by the inserted leads allows for robust connections, making it suitable for applications that experience physical stress or vibration, such as industrial machinery and military devices. Moreover, Through Hole PCB Assembly is integral in prototyping and low-volume production where modifications may still be needed. This technique also leverages standardized components, simplifying sourcing and inventory management.

Common Applications of Through Hole PCB Assembly

Practically, Through Hole PCB Assembly is employed in various sectors. Among the common applications are:

- Consumer Electronics: Used in devices that require durable and high-performance PCBs, such as audio amplifiers and televisions.

- Automotive: Essential for components that must endure considerable strain and varying environmental conditions, such as power supplies and sensor systems.

- Medical Devices: Vital for ensuring reliability in life-saving equipment like pacemakers and imaging systems where failure is not an option.

- Industrial Applications: Applied in control systems, automation equipment, and robotics where durability is paramount.

Advantages of Through Hole PCB Assembly

Durability and Reliability of Through Hole PCB Assembly

The intrinsic structural integrity of Through Hole PCB Assembly provides unparalleled durability. This assembly technique allows components to be securely fastened into the PCB, which is particularly beneficial in high-stress environments. By utilizing mechanical retention, the leads of the components are less likely to shake loose, ensuring a long-lasting and reliable connection. Additionally, this approach excels in thermal dissipation, as the heat generated by electronic components is effectively spread across the PCB material.

Design Flexibility with Through Hole PCB Assembly

Another significant advantage is the design flexibility it offers engineers. Through Hole PCB Assembly accommodates a wide range of component sizes and types, from discrete resistors and capacitors to larger, more complex components such as connectors and transformers. This versatility enables innovative designs and allows for easy modifications during prototyping stages, which is critical in creating effective electronic systems that meet precise specifications.

Cost Implications of Through Hole PCB Assembly

While Through Hole PCB Assembly may have higher initial labor costs due to manual soldering in many cases, it can result in lower overall production costs for smaller batches. The longevity and reliability of boards produced via this method can mitigate those costs over time by reducing the incidence of failure and the associated maintenance expenses. Moreover, the use of readily available components can further help in controlling costs for manufacturers working within budget constraints.

Challenges in Through Hole PCB Assembly

Manual Processes and Labor Intensity in Through Hole PCB Assembly

One of the primary challenges facing Through Hole PCB Assembly is the labor-intensive nature of the process. Manual soldering can be time-consuming and may introduce variability, making it more difficult to achieve consistent quality. As a result, companies often face constraints related to production speed and labor costs, especially when trying to scale operations. Adopting automation, where possible, and implementing standardized training for workers can help mitigate these issues.

Quality Control Measures for Through Hole PCB Assembly

Ensuring the quality of Through Hole PCB Assembly demands rigorous quality control measures. The dual challenges of physical handling and manual soldering necessitate inspection processes such as visual inspections and automated optical inspection (AOI) to identify defects early in the production cycle. Establishing a robust quality management system, including routine maintenance and calibration of equipment, ensures that assembly standards are upheld.

Common Defects in Through Hole PCB Assembly and Solutions

Common defects in Through Hole PCB Assembly include cold solder joints, bridging, and component misalignment. Cold solder joints, often caused by insufficient heating during soldering, can be resolved by improving training or adopting better soldering techniques. Bridging—where solder shorts adjacent leads—can be minimized by employing solder paste instead of traditional methods and by adhering to design guidelines for pad sizes. Regular inspections during the assembly process can identify misaligned components early, allowing for corrective actions before further assembly steps are taken.

Best Practices for Through Hole PCB Assembly

Design Guidelines for Through Hole PCB Assembly

Effective design is paramount for successful Through Hole PCB Assembly. Designers should observe the following guidelines to enhance assembly efficiency and end-product reliability:

- Appropriate Hole Sizes: Ensure holes are correctly sized to accommodate component leads while considering tolerances for solder flow.

- Clearances: Maintain adequate spacing between components to prevent overheating and allow for solder flow.

- Test Points: Incorporate test points in the design to facilitate easy access during quality assurance.

Soldering Techniques for Effective Through Hole PCB Assembly

Implementing effective soldering techniques can significantly enhance the quality of Through Hole PCB Assembly. Options range from manual soldering with a soldering iron to automated soldering processes like wave soldering or reflow soldering. The technique chosen depends largely on the production scale and the complexity of the assembly. Consistency in soldering practices is crucial, so training personnel in best practices and utilizing soldering guidelines will ensure reliability.

Testing and Validation Processes in Through Hole PCB Assembly

Testing and validation are critical components of the Through Hole PCB Assembly process. Both functional testing and stress testing should be employed to validate that the assembled PCBs meet specified performance criteria. Leveraging automated testing equipment can enhance efficiency while minimizing human error. Documenting test results allows for continual improvement and compliance with industry standards.

Future Trends in Through Hole PCB Assembly

Technological Innovations Impacting Through Hole PCB Assembly

The future of Through Hole PCB Assembly is being shaped by ongoing technological innovations. Advances in materials, such as lead-free solder and eco-friendly substrates, are expanding the usability of Through Hole methods in new markets. Additionally, the integration of smart manufacturing technologies, such as the Internet of Things (IoT) and data analytics, is facilitating real-time monitoring of production and quality metrics, leading to improved efficiencies.

The Role of Automation in Through Hole PCB Assembly

The increasing demand for higher precision and reduced production times has prompted the integration of automation in Through Hole PCB Assembly. Automated soldering techniques are becoming more prevalent, allowing for consistent quality and faster turnaround times. Robotics and placement machines are now capable of executing delicate assembly processes that were once performed manually, thus reducing labor costs and enhancing scalability.

Predictions for the Evolution of Through Hole PCB Assembly

As technology continues to advance, the evolution of Through Hole PCB Assembly is poised for growth. Industry experts predict a balanced coexistence with Surface Mount Technology (SMT), with each method serving unique applications. An inclination towards hybrid assemblies that integrate both technologies is expected, as manufacturers adapt to the increasing complexity of electronic devices. Furthermore, a stronger emphasis on environmental sustainability is likely to influence material choices and manufacturing processes moving forward.