Introduction to Electromagnetic Shielding Materials

With the proliferation of electronic devices in our daily lives, the significance of electromagnetic shielding materials has escalated rapidly. These materials are used to protect sensitive electronic equipment from electromagnetic interference (EMI) and radio frequency interference (RFI), ensuring optimal performance and safety. In this article, we will delve into the nature of electromagnetic shielding materials, their applications, the types available, best practices for implementation, and emerging trends in this vital area of technology.

What Are Electromagnetic Shielding Materials?

Electromagnetic shielding materials are specialized substances designed to block or attenuate electromagnetic fields. They create a barrier that prevents electromagnetic waves from interfering with the performance of electronic devices. Shielding effectiveness is determined by several factors, including the material’s conductivity, thickness, and magnetic permeability. Common materials used for EMI shielding include metals, conductive polymers, and composite materials.

Why Use Electromagnetic Shielding?

The necessity for electromagnetic shielding arises from the increasing complexity and density of electronic circuits and systems. Electromagnetic interference can lead to degraded performance, data loss, and even catastrophic failures in sensitive equipment—highlighting the importance of effective shielding solutions. Some reasons for using electromagnetic shielding materials include:

- Protection of equipment: Shielding protects sensitive electronic devices, such as medical equipment, communication systems, and computing hardware, from noise and interference.

- Compliance with regulations: Many industries must adhere to stringent regulations regarding EMI emissions. Shielding ensures compliance, thereby avoiding fines and legal repercussions.

- Improved signal integrity: Shielding helps maintain the quality of signaling in circuits, ensuring that electronic devices operate at optimal capacity without disruption from external EMI sources.

Common Applications of Electromagnetic Shielding

The applications of electromagnetic shielding materials are vast and varied, spanning multiple industries. Key areas where shielding is critical include:

- Medical Devices: Equipment such as MRI machines and other diagnostic tools require high levels of shielding to function accurately and safely.

- Consumer Electronics: Mobile phones, laptops, and other consumer devices incorporate shielding materials to enhance performance and user experience.

- Telecommunications: Shielding is essential in the development of devices used in wireless communication to minimize interference and maintain signal quality.

- Aerospace and Defense: The aerospace industry utilizes advanced shielding solutions for avionics systems, protecting them from EMI that could compromise flight safety.

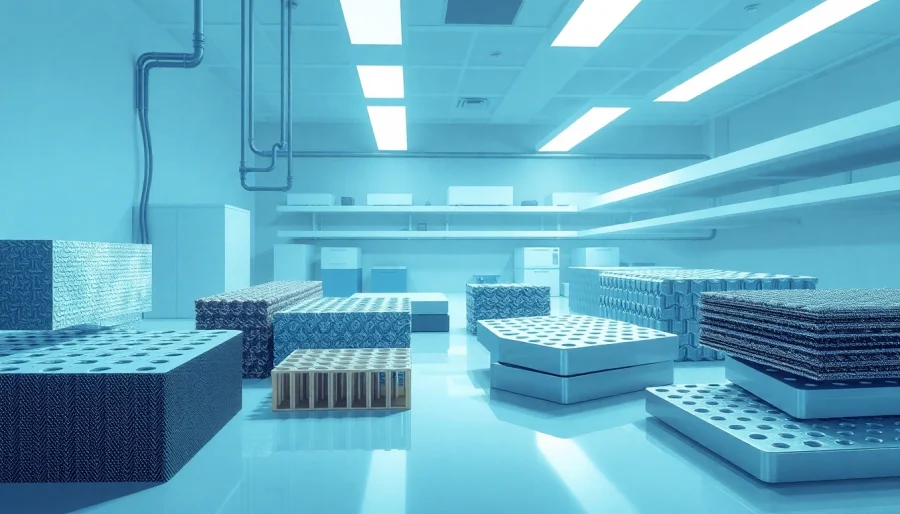

Types of Electromagnetic Shielding Materials

Metals: The Most Popular Choice

Metals are the most widely used materials for electromagnetic shielding, thanks to their high electrical conductivity and effectiveness. The following metals are commonly utilized for this purpose:

- Copper: Known for its excellent electrical conductivity, copper is often regarded as the gold standard in shielding materials. Its ability to attenuate both electric and magnetic fields makes it a top choice for various applications.

- Aluminum: Lightweight and cost-effective, aluminum offers good shielding capabilities and is commonly used in consumer electronics and architectural applications.

- Nickel: With its corrosion resistance and durability, nickel is frequently used in combination with other metals to enhance shielding.

- Steel: Both stainless and electrical steel provide robust shielding solutions and are often used in industrial applications, where durability is essential.

Conductive Polymers and Their Uses

Conductive polymers are a growing category of materials that offer flexibility and lightweight characteristics alongside decent shielding properties. Some benefits include:

- Flexibility: Unlike metals, conductive polymers can be easily molded into various shapes, making them suitable for unconventional designs.

- Cost-Effectiveness: They can be less expensive than metals, especially in high-volume applications where production costs are critical.

Common applications include flexible circuit boards and EMI shielding coatings for surfaces.

Alternative Materials for Shielding

Beyond metals and conductive polymers, several alternative materials have emerged as effective EMI shielders:

- Metals Screens and Foams: Metal screens and foams can provide effective shielding while being light and adaptable. They often serve as enclosures or linings in electronic devices.

- Composite Materials: Combining different substances can significantly enhance shielding properties. For example, composites that incorporate carbon nanotubes show promise for future applications due to their high strength and conductivity.

- Ceramics: Certain ceramics exhibit conductive properties, making them suitable for electromagnetic shielding in specific applications, such as high-temperature environments.

How to Select the Right Electromagnetic Shielding Material

Factors to Consider When Choosing

Selecting the appropriate electromagnetic shielding material involves considering various factors that can impact performance:

- Frequency Range: Different materials respond uniquely to various frequencies. Understanding the frequency range of the electromagnetic waves you wish to block is crucial in selecting a suitable material.

- Environmental Conditions: Consider the operating environment—temperature, humidity, and exposure to chemicals can all influence material performance.

- Thickness and Weight: Depending on application requirements, the thickness and weight of the shielding material should be assessed for practicality and performance requirements.

Cost vs. Performance Analysis

While performance is essential, the cost associated with different shielding solutions can vary considerably. Conducting a cost-benefit analysis is vital:

- Material Costs: While metals generally offer superior shielding, they may also lead to higher upfront costs. Conductive polymers may present a more economical option in particular scenarios.

- Long-term Reliability: Assessing potential long-term savings through durability and performance stability over time can make a cheaper product less appealing if it doesn’t stand up under pressure.

Testing and Certification Standards

Once a material is selected, it must undergo rigorous testing to ensure it meets relevant standards and specifications. Certification might be required depending on the intended use, such as:

- Federal Information Processing Standards (FIPS): Often applicable in government and military applications.

- Telecommunication Certification: These certifications ensure that devices comply with FCC regulations concerning EMI emissions.

Best Practices for Implementing Electromagnetic Shielding

Installation Techniques for Maximum Effectiveness

Achieving maximum effectiveness from shielding materials depends heavily on installation techniques. Some best practices include:

- Seamless Connections: Ensure seamless connections between shielding materials to prevent gaps that would allow EMI penetration.

- Proper Grounding: Grounding shielding materials is vital in effectively diverting electromagnetic interference away from sensitive components.

- Environmental Considerations: Evaluate the installation environment to choose appropriate adhesives and sealants that will maintain shielding performance over time.

Regular Maintenance and Monitoring

Regular inspection and maintenance of EMI shielding are necessary to ensure continued effectiveness. This includes:

- Visual Inspections: Look for signs of wear and tear, corrosion, or damage to the shielding materials.

- Performance Testing: Schedule periodic testing to ensure the shielding is functioning correctly, especially in critical applications.

Common Mistakes to Avoid

When implementing electromagnetic shielding, it is essential to avoid common pitfalls such as:

- Ignoring Frequency Needs: Selecting materials based solely on general characteristics rather than specific frequency needs can lead to ineffective shielding.

- Neglecting Grounding: Failing to ground shielding properly can diminish its effectiveness drastically, exposing devices to interference.

Future Trends in Electromagnetic Shielding Materials

Innovations in Material Science

The field of electromagnetic shielding is ever-evolving, particularly with advancements in material science. Innovative materials, such as metamaterials, are offering new levels of performance by manipulating electromagnetic structures at the nano-scale. This could revolutionize the effectiveness of shielding solutions in the near future.

Sustainability and Eco-friendly Options

As industries move towards sustainable practices, the demand for eco-friendly materials has grown. Research into biodegradable conductive polymers and recycling techniques for metals is underway, aiming to reduce the environmental impact of electronic waste and shielding materials.

Emerging Technologies Impacting Shielding Solutions

With the rise of IoT devices and 5G technologies, new challenges arise in terms of electromagnetic compatibility. Future shielding solutions will need to address these challenges, including developing ultra-thin, flexible materials without compromising effectiveness. Additionally, smart shielding solutions that can adapt to varying electromagnetic environments are on the horizon.